- July 15, 2023

- Vikrant Adams

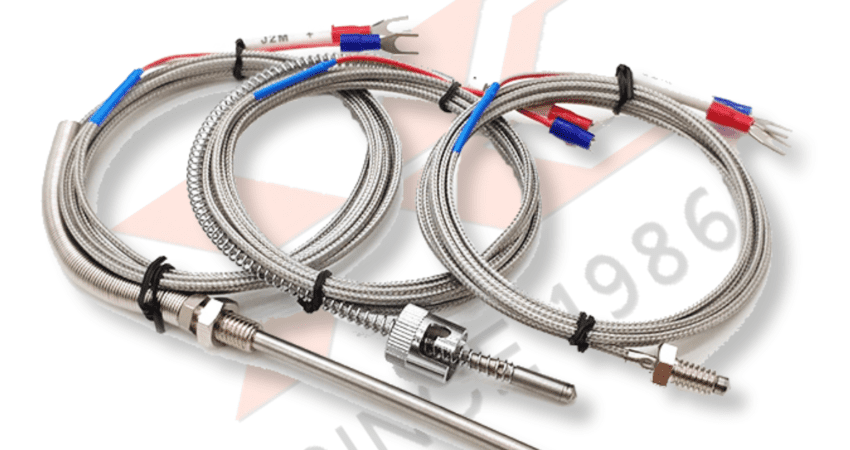

1. Introduction to Thermocouples: A thermocouple is a type of temperature sensor that operates on the principle of the Seebeck effect. It consists of two dissimilar metal wires joined at one end to form a junction. When there is a temperature difference between the junction and the other end of the wires, an electromotive force (EMF) is generated. This EMF is directly proportional to the temperature difference, allowing thermocouples to measure temperature accurately.

2. Types of Thermocouples: There are various types of thermocouples, each suited to specific temperature ranges and applications. Common types include Type K (Chromel-Alumel), Type J (Iron-Constantan), Type T (Copper-Constantan), Type E (Chromel-Constantan), and many others. The choice of thermocouple type depends on the temperature range, environment, and required accuracy for the specific industrial process.

3. Advantages of Thermocouples:

- Wide temperature range: Thermocouples can measure temperatures ranging from -200°C to over 2300°C, making them suitable for a broad range of industrial processes.

- Fast response: Thermocouples offer rapid response times, enabling real-time temperature monitoring and control.

- Rugged and durable: Thermocouples are robust and can withstand harsh environments, making them suitable for demanding industrial applications.

- Versatility: With various types and configurations available, thermocouples can be used in different industries and processes.

4. Applications of Thermocouples in the Process Industry:

- Heat Treatment: In heat treatment processes like annealing, tempering, and quenching, precise temperature control is essential to achieve the desired material properties.

- Chemical Processing: In chemical reactions, controlling temperature is crucial to ensure product quality, optimize reaction rates, and prevent safety hazards.

- Food Industry: In food processing and storage, temperature monitoring is critical to maintain freshness, prevent spoilage, and ensure compliance with safety regulations.

- Pharmaceuticals: Temperature control is vital in pharmaceutical manufacturing to maintain the effectiveness and safety of drugs.

- Energy Production: Thermocouples play a role in monitoring and optimizing temperature in power plants and other energy production facilities.

- Metallurgy: In metalworking processes like welding and casting, precise temperature measurements are crucial for achieving desired material properties.

5. Best Practices for Thermocouple Usage:

- Regular Calibration: To maintain accuracy, thermocouples should be calibrated regularly, especially if they are used in critical applications.

- Correct Placement: Proper positioning of thermocouples within the process is essential to obtain accurate readings. Placement should consider factors such as heat distribution, potential interferences, and safety.

- Quality Control: Ensuring the quality and accuracy of thermocouples is vital to obtaining reliable temperature data. Using high-quality thermocouples and accessories will enhance overall performance.

Conclusion: Thermocouples are invaluable tools in the process industry for accurate temperature measurement. Understanding the principles behind thermocouples and their applications empowers industrial operators to optimize processes, improve product quality, and enhance overall efficiency. By employing best practices in thermocouple usage, industries can harness the benefits of these temperature sensors to achieve their operational goals effectively.