- October 12, 2023

- Vikrant Adams

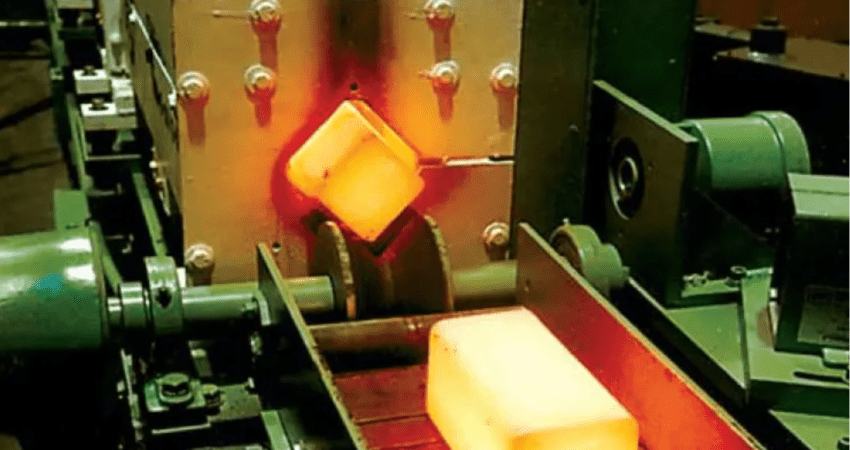

In the forging industry, precision and control are paramount to achieve high-quality, reliable, and durable forged products. One crucial aspect of this process is the accurate measurement of temperature during die heating. Dies, which play a vital role in shaping raw materials into sturdy components, need to be heated to precise temperatures depending on the type of metal being forged. In this article, we will explore the importance of temperature measurement during die heating and how thermocouples and RTDs (Resistance Temperature Detectors) play a significant role in this critical phase of the forging process.

Die Heating in the Forging Industry

Die heating is a crucial step in the forging industry, and the success of this process greatly depends on the accuracy and control of temperature. Dies are heated to specific temperatures, typically ranging from 300 to 600 degrees Celsius, depending on the type of metal that is being forged. This precision ensures that the metal remains malleable and can be shaped effectively. To achieve this level of control, temperature sensors like thermocouples and RTDs are employed.

Thermocouples for Die Heating

- Type K Thermocouples: Type K thermocouples are a popular choice for die heating temperature measurement. They offer a wide temperature range and are well-suited for high-temperature applications. These thermocouples consist of two different metal wires, joined at one end, which generate a voltage proportional to the temperature difference. Type K thermocouples are durable and can provide accurate temperature readings in the challenging conditions of a forging shop.

- Mineral Insulated Thermocouples: Mineral insulated thermocouples are designed for high-temperature environments. They are encased in a mineral insulation material that allows them to withstand extreme heat. In addition, they feature a stainless steel (SS310) protection sheath, which provides further resistance to high temperatures and environmental factors. The IP 65 head ensures the thermocouple remains protected from dust and moisture.

RTDs for Die Heating

- Pt-100 RTDs: Pt-100 RTDs are another reliable choice for temperature measurement during die heating. These sensors are known for their high accuracy and stability. They are available in both 3-wire and 4-wire configurations, allowing for precise temperature measurement. Additionally, Pt-100 RTDs can be equipped with protection sheaths made of high-temperature materials such as SS304, SS316, and Hastealloy to ensure durability in the harsh conditions of the forging industry.

Conclusion

In the forging industry, precision in die heating is critical for producing high-quality and reliable forged products. Accurate temperature measurement during this process is achieved through the use of thermocouples and RTDs. Type K thermocouples and mineral insulated thermocouples, along with Pt-100 RTDs, are reliable temperature sensors that can withstand the high temperatures and demanding conditions of the forging environment. These sensors play a vital role in ensuring that dies are heated to the precise temperatures required for the successful forging of various metals. By using these temperature measurement tools, the forging industry can continue to deliver products of exceptional quality and durability.