In the dynamic world of manufacturing, precision and control are paramount. This holds true in industries where materials undergo various transformations, such as the rubber industry. Temperature management plays a crucial role in the rubber production process, ensuring that the end product meets the highest quality standards. In this article, we will explore how temperature control is a key factor in the rubber industry and how Yog Electro Process can help ensure optimal results.

Understanding Rubber Production:

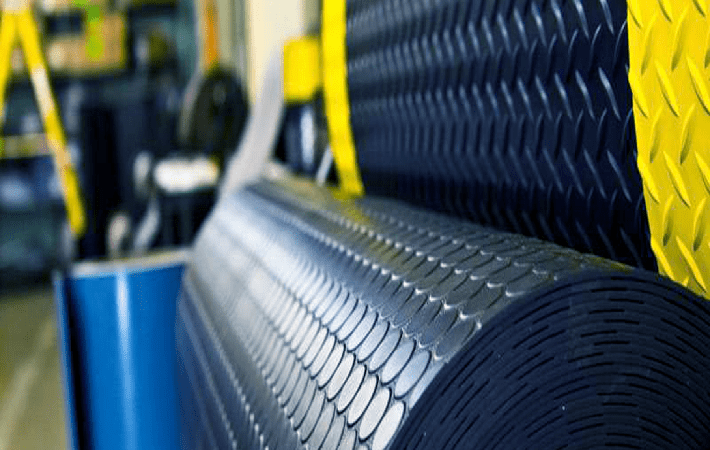

Rubber is a versatile material used in countless products, from tires to industrial seals and consumer goods. The production of rubber involves a complex series of chemical and physical processes. Rubber compounds are mixed, shaped, and cured at specific temperatures and under precise conditions. Any deviation from the recommended temperature range can result in the degradation of the material, leading to subpar products and increased waste.

Temperature Control in Rubber Manufacturing:

- Mixing and Compounding: Rubber compounds are created by blending various ingredients, including elastomers, fillers, and chemicals. This process requires precise temperature control to ensure that the components mix evenly and thoroughly. Yog Electro Process’s Digital Temperature Indicators/Controllers can help maintain the optimal temperature, ensuring consistent rubber quality.

- Molding and Vulcanization: After mixing, rubber is shaped into its final form and vulcanized. Vulcanization is the process of curing rubber by exposing it to heat. Controlling temperature during vulcanization is critical, as it directly affects the material’s properties, such as hardness, elasticity, and durability. Yog Electro Process’s Temperature Transducers and Heaters are designed to provide the accuracy and reliability necessary for this stage.

- Quality Assurance: To maintain product quality, real-time monitoring of temperature is essential. Yog Electro Process’s Recorders, Transmitters, and Scanners enable manufacturers to track and record temperature data, ensuring consistency and compliance with quality standards.

Why Choose Yog Electro Process:

Yog Electro Process, with over 35 years of experience in the industry, has established itself as a leading manufacturer of temperature control solutions. The company’s commitment to quality and accuracy, along with its ISO/IEC: 17025:2017 NABL LAB for Thermal Products, makes it a trusted partner for the rubber industry. With a broad temperature range from -20°C to +1100°C, Yog Electro Process can meet all your temperature-related needs.

Conclusion:

In the rubber industry, precision in temperature control is non-negotiable. Yog Electro Process’s range of Temperature Transducers, Digital Temperature Indicators/Controllers, Recorders, Transmitters, Scanners, and Heaters ensures that manufacturers can maintain the quality and reliability of their rubber products. Choosing Yog Electro Process as your temperature control partner means taking a step towards achieving the highest product quality standards and reducing waste in the rubber production process.

For more information and to explore how Yog Electro Process can meet your specific temperature control needs in the rubber industry, please feel free to contact us. We are dedicated to enhancing your production efficiency and product quality.